Robotic arms are a showcase of engineering innovation, they're used is all sorts of complex assembly lines from cars to food production but how do they work? In this blog we're going to take a look at some robotic arms and also look at some of the main features most robotic arms will have.

|

|

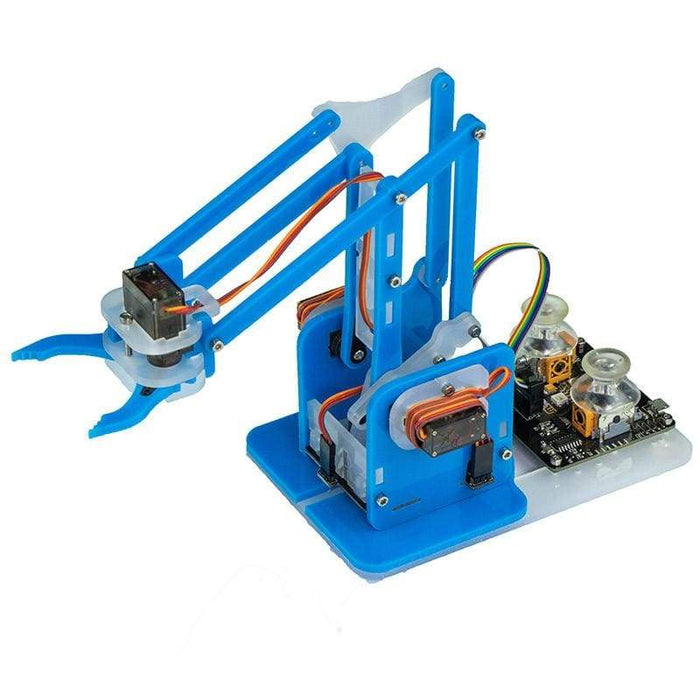

| Dobot Magician - Basic Version | MeArm Robot (Arduino) |

There are a number of different types or Robotic arms but the most common and the type we primarily stock are Articulated Robots meaning they have three rotary joints. Robotic arms are designed to emulate the human arm so it makes sense that a lot of the parts and features they have relate to parts of a human arm.

Joints

Like a human arm has joints so does a Robotic arm, these allow the arm to move and also determine the limits of it's movement and rotations. The joints move the different parts of the arms using the connected motors, the control unit powers and sends instructions to the motors which correspond to different movements. Usually the number of joints will be the same as the degrees of freedom (DoF) which is the number of movable joints.

End Effectors

The end effector of a robotic arm connects at the wrist joint and produces the end result or action desired. This section acts as the hand and wrist and performs actions such as gripping an item, lifting an item via suction, engraving and so much more.

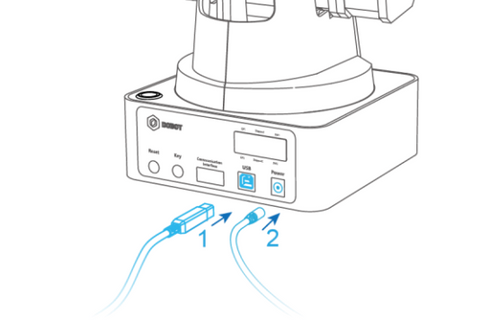

Main Control Unit

This is the brain of the arm, it in most cases houses the arms controller and is where you'll connect the cables needed to power and program the arm. On some robotic arms this will also be where you connect any external sensors or other devices such as conveyor belts.

Sensors

Most robotic arms will use some form of sensor to complete their desired operations and provide feedback about the surrounding enviroment. This could be anything from a camera for item recognition to a temerature sensor for safe operation on a laser. This all help the robots to perform in a controlled way and intergrate with other systems.